Bearing Components

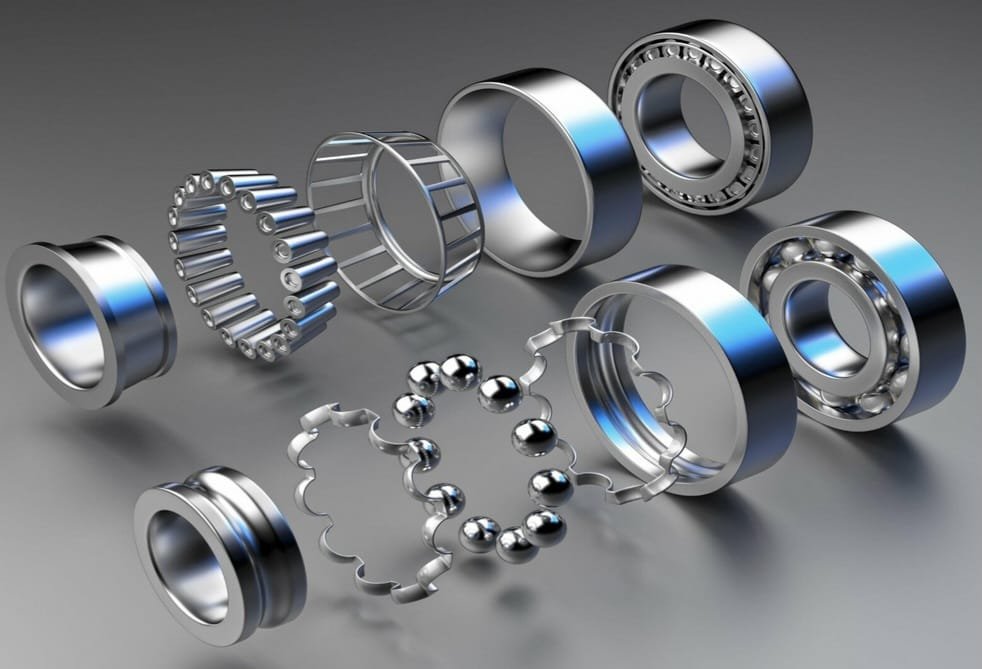

Bearings usually consist of the following components: Two rings or discs with raceways. Rolling elements in the form of rollers or balls. A cage which keeps the rolling elements apart and guides them.

Angle rings (L-shaped thrust collars) are used either with NU design cylindrical roller bearings to locate the shaft axially in one direction, or with NJ design bearings to locate the shaft axially in both directions. The rings are made of carbon chromium steel and are hardened and ground. They are supplied as separate components.

They are simple to install and require no additional space on the shaft. When utilized on plain shafts, the bearing can be installed at any place along the shaft. When utilized on stepped shafts with an L-shaped spacer ring, the bearing can be correctly axially positioned, making bearing installation and removal easier.

Needle roller bearings contain needle rollers as rolling elements. In rolling bearing technology, cylindrical rolling elements are classed as needle rollers if their diameter is ≥6 mm and the diameter-to-length ratio is Dw/lw = 1:3.

Because of the small diameter of the rolling elements, all needle roller bearings have the same low radial section height. Because of the line contact, they are ideal for bearing arrangements with a high radial load carrying capacity and stiffness in a limited radial design space.

Steel balls are the primary components of ball bearings. Steel balls are of high quality, with high load bearing capacity and hardness. Steel balls are utilized in automotive applications for semi-precision bearings, as well as commercial uses including casters, locks, and drawer slides.

High precision bearing sleeves are utilized in a wide range of applications. Bearing sleeves or adapter sleeves act as a mounting surface for bearings. When utilized with spacer sleeves, additional shaft components can be appropriately positioned. This configuration also makes it easier to disassemble the bearing in applications that demand frequent installing and dismounting.